FLEXIBILITY AND QUALITY TROUBLESHOOTING IN A VENETIAN CUSTOMER COATERS

FLEXIBILITY AND QUALITY TROUBLESHOOTING IN A VENETIAN CUSTOMER COATERS

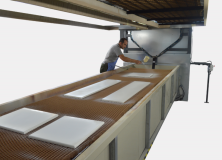

THE NEW CAROUSEL PLANT

«Thanks to suggestions from Colorservice technicians, I could contact Vidali Finishing of Motta di Livenza. This company analysed our working agenda and came up with this solution». The coating booth is made for a single coater, this is the reason why the tray rotates by 180° thanks to a specifically designed central pivot. «Even though my budget was limited, Vidali Finishing was able to manufacture a high-end equipment, which is extremely important in order to achieve a top-quality coating: the coating booth for finishing is pressurized, the controlled temperature oven can contain up to 50 trays per coating booth - thanks to this I have no trolleys left around at the end of a workday - the individual coating is made easier by the

rotation mechanism of the trays». The coating plant for doors,panels and window frames is composed by two booths containing a carousel conveyour for trays. It is equipped with 100 trays of great dimension (5000x1200 mm), and can be operated by a single worker who oversees all operations of coating, loading, and manipulation during the coating phase. Thanks to the carousel conveyor it is possible to store the coated pieces in the drying tunnel just above the working positions, which comprises different floors. the vertical height of the plant is fully exploited in this way.

DOWNLOAD THE EDITORIAL "VDL - Verniciatura del legno" TO CONTINUE READING